Coconuts assume an indispensable role in Malai’s endeavours as a biomaterial manufacturing brand; they have unlocked the potential of bacterial cellulose, a truly exceptional natural material cultivated through the intricate art of fermentation. The aspect which captures people’s attention is that Malai’s material is actually derived from coconut water. This revelation has coincided with a broader shift that is taking root, especially within industries like fashion. People are becoming increasingly open to exploring alternative materials and diversifying their understanding of what could replace leather.

The brand’s inception can be traced back to the collaborative efforts of two individuals: Susmith, a skilled product designer and artisan hailing from the scenic province of Kerala in South India, and Zuzana, a dedicated material researcher and designer originating from Slovakia. In 2017, they made a deliberate choice to relocate to a region in Southern India renowned for its abundant coconut cultivation, after which they committed themselves entirely to the development of Malai, which is a fabric entirely made out of coconuts and coconut water.

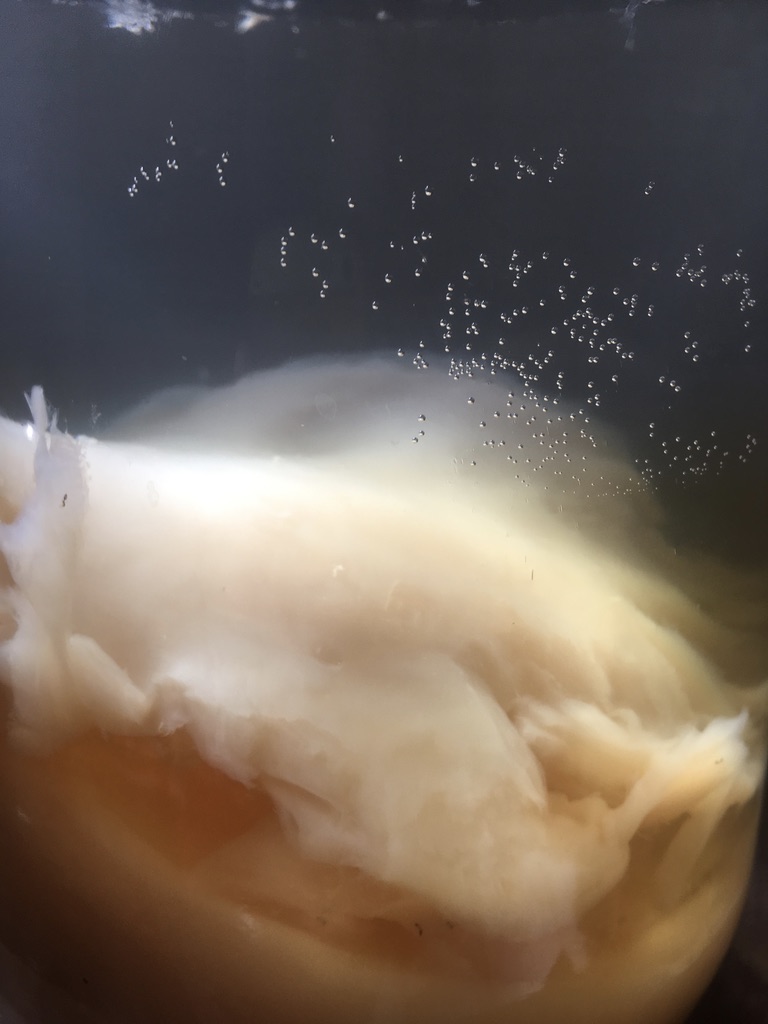

This resource (coconut water) is often squandered as waste within coconut processing facilities. Typically, the purpose of coconuts revolves around the extraction of their flesh and milk, leaving the residual as an afterthought. By repurposing this overlooked coconut water into a medium for bacterial cellulose fermentation, Malai embraces a more sustainable approach and transforms what would otherwise be discarded as waste, into a resource of ecological worth.

Malai

The process

Creating the perfect conditions for bacteria to thrive and generate cellulose is the linchpin of this endeavour. What elevates this process is the suitability of water sourced from mature coconuts as an exceptional growth medium for bacterial cellulose. Its appeal lies in its minimalist requirements, demanding only a scant few additional components to facilitate the flourishing of these microorganisms.

In the case of obtaining fibres from banana plants, the usual practice involves farmers harvesting the banana fruit, leaving the banana stem or plant neglected. Initially, this endeavour was challenging. Few were aware of the opportunity, which led to a lack of willingness to invest in the necessary machinery and infrastructure. The uncertainty surrounding output volume and other logistical aspects complicated the situation, but Zuzana and Susmith partnered with individuals who were motivated to address the waste generated on their farms, marking the nascent phase of their collaboration.

In the early stages, the expectation revolved around finding leather substitutes that resembled leather’s appearance and characteristics, but with a touch of magic, implying that it isn’t actually leather. Today, we can observe a noticeable shift in this perspective. People have become more receptive to a wider spectrum of materials, embracing new options with distinct aesthetics and unique properties.

Malai’s attempt at staying sustainable is visible since they employ plant-based dyes throughout the production of their bio-composite material, sourcing them from suppliers in the northern regions of India. They have partnered with a company that has pioneered the cold bath dyeing method, an approach that aligns seamlessly with their requirements. This allows an infusion of an array of colours into the fibres that constitute their material, allowing for diverse shapes and hues. Their palette, staying close to nature, includes natural sources like Indigo, Mother Marigold, and various plant components.

Since their products are entirely organic, they naturally entail some variations over time. Exposure to UV light and other climatic conditions subtly influence the intensity of the colours. However, the team at Malai has fine-tuned their colour formulations to ensure both short-term and long-term stability. These colours are not just biodegradable; they are also home compostable, aligning with Malai’s commitment to environmental sustainability.

Naturally dyed coconut leather

Although Malai mainly manufactures fabrics, they do have their own products. Using their dyed material and sustainably designed aesthetic, they have a range of bags, pouches, and coin purses.

“I find it difficult to single out a favourite among the many pieces we’ve created. Our materials are inherently dynamic, ensuring that even those produced in 2018 differ somewhat from our current output. Every product and production batch possesses a unique essence, making it challenging to pinpoint a singular favourite,” Zuzana shares, discussing the various products that have been created using Malai’s manufactured “leather”.

“My true passion lies in the continuous learning process associated with the material I am deeply involved in,” says Zuzana, bringing her perspective as a designer to the forefront. “It’s a remarkable journey marked by constant discovery, debunking the myth that inventing something means you know it inside out. We learn new facets every day.”

Zuzana shares that Susmith and her are most excited from the convergence of their capabilities, the manufacturers’ expertise, and the creativity of designers. Witnessing how different brands utilise their materials is a source of great satisfaction for the founders. Some are adept at harnessing the material’s unique attributes, refraining from merely trying to replicate leather. “It’s gratifying to observe when they invest the time and attention required to comprehend the material and bring forth its distinctive qualities.”

Products made out of Malai’s biomaterials (coconut leather)

“I believe that the fascination I experience with the material I work on is not unique to this specific material but rather a common trait among individuals deeply immersed in material development,” says Zuzana, the co-founder of Malai. “This journey has served as a profound introduction to the intricate realm of cellulose materials, offering a deeper understanding that transcends my prior experiences (as a designer).”

Having worked with cellulose materials as a designer and end-user in the past, Zuzana’s involvement delves into the granular details of their composition, behaviour, and adaptability. Cellulose, as one of the world’s most abundant materials, holds a pivotal role in the future, a significance likely to increase over time.

What truly sets cellulose materials apart is their innate natural essence. Cellulose behaves distinctively, responding to varying geographical locations and climatic conditions, distinguishing it from synthetic materials. For Zuzana and the evolution of Malai, the most captivating aspect of the cellulose-based materials they work with is their intricate relationship with moisture and atmospheric humidity. These factors hold the power to profoundly influence the characteristics and properties of cellulose-based material, reflecting the dynamic nature of the natural world.

Words by Esha Aphale.

Image courtesy Malai.